How to Fail Your Municipality's Residential Mechanical Rough-In Inspection.

By Murray Wennerlund published 9-16-2024 updated 9-16-2024

1. Structural Plates Across Top Plate [IRC 602.6.1]:

This requirement ensures proper reinforcement where pipes, ducts, or wiring run through the top plates of a wall, particularly in load-bearing walls. Structural plates help maintain the integrity of the framing.

Reasons for Failure:

- Improper or missing reinforcement plates where penetrations occur.

- Non-compliance with minimum plate thickness or material type.

- Structural members weakened by overcutting without reinforcement.

2. Nail Protection [IRC 1308.2.1]:

Protection plates (nail guards) must be installed to shield electrical wiring, plumbing or HVAC lines running through studs or framing to prevent accidental puncture from nails or screws.

Reasons for Failure:

- Missing nail plates where required.

- Plates installed improperly or of insufficient size.

- Insufficient coverage of wiring or piping near the surface.

3. Dryer Vent Material &;; Distances [IRC 1502]:

Regulates the proper materials and maximum allowable length for dryer ducts to ensure safe venting and reduce fire hazards.

Reasons for Failure:

- Use of improper duct material (e.g., flexible plastic).

- Exceeding the maximum allowable vent length without a booster fan.

- Improper installation, such as excessive bends or sagging ducts.

4. Range Hood Venting [IRC 1503]:

Ensures proper venting of range hoods to the outside of the building to expel heat, grease, and fumes.

Reasons for Failure:

- Failure to vent outdoors (venting into attic or other spaces).

- Using improper duct material (e.g., flexible plastic).

- Incorrect termination location (e.g., too close to windows or intake vents).

5. Bath Exhaust Fan Requirements [IRC 1507.4]:

Bathroom exhaust fans must vent moisture-laden air outside to prevent mold and moisture damage.

Reasons for Failure:

- Exhaust fan not vented to the exterior (venting into attic or ceiling space).

- Inadequate fan capacity for the room size.

- Duct runs with improper length or excessive bends.

6. Bathroom Exhaust Duct Length [IRC 1506.2]:

Regulates the maximum length of bathroom exhaust ducts to ensure efficient moisture removal.

Reasons for Failure:

- Exceeding maximum allowable duct length.

- Too many bends or improper slope in the duct run.

- Use of materials not rated for bathroom exhaust ducts.

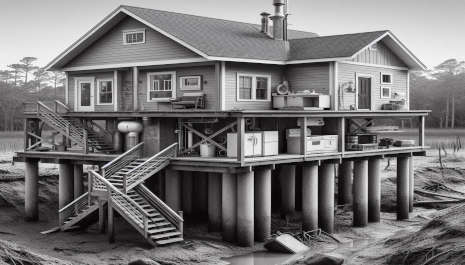

7. Equipment Platforms &;; Access [IRC 1305]:

Requires that mechanical equipment, like HVAC units in attics or crawl spaces, have adequate platforms and access for maintenance and servicing.

Reasons for Failure:

- Inadequate or missing access pathways or platforms.

- Improper clearances around the equipment.

- Lack of lighting or service outlets near equipment.

8. Equipment Sizing Matches Plans (if accessible):

Mechanical equipment installed should match the size and specifications indicated in the building plans to ensure proper function.

Reasons for Failure:

- Installed equipment does not match the specified plans.

- Undersized or oversized units leading to efficiency or safety issues.

- Improper installation location.

9. Drip Pan Overflow Protection [IRC 1411.3.1]:

Requires overflow protection for HVAC systems (like AC units) to prevent water damage from condensate overflow.

Reasons for Failure:

- Missing or improperly installed drip pans.

- Lack of a secondary drain line or float switch.

- Improper drainage slope for condensate lines.

10. Duct Layout and Sizing Matches Plans:

Ductwork layout and sizing should follow the building plans to ensure proper airflow and system balance.

Reasons for Failure:

- Ductwork that doesn't match the approved plans.

- Improper sizing leading to inadequate airflow or excessive noise.

- Incorrect placement of ducts or registers.

11. Duct Support [IRC 1601.4.4]:

Ductwork must be adequately supported to prevent sagging, disconnection, or improper airflow.

Reasons for Failure:

- Insufficient or incorrectly spaced supports.

- Sagging or disconnected duct sections.

- Use of improper fasteners or support materials.

12. Fireplace &;; Chimney Clearances [IRC 1003.18, IRC 1005.1]:

Ensures proper clearance between fireplaces/chimneys and combustible materials to prevent fire hazards.

Reasons for Failure:

- Clearances between chimney and combustible materials are not met.

- Improper materials used for chimney construction.

- Inadequate firestopping around the chimney.

13. Factory-Built Fireplace Exterior Air [IRC 1006.1.1]:

Factory-built fireplaces must be designed to draw combustion air from the outside to reduce indoor air pollution and improve efficiency.

Reasons for Failure:

- Missing or inadequate exterior air intake.

- Improper installation of exterior air ducts.

- Lack of proper termination for exterior air intake.

14. Gas Piping Support &;; Size [IRC 2413, IRC 2418]:

Gas pipes must be properly sized and supported to prevent leaks and ensure safe gas flow.

Reasons for Failure:

- Improper pipe sizing for the appliance.

- Inadequate support leading to sagging or stress on connections.

- Use of improper materials or fittings.

15. Gas Piping Test [IRC 2417]:

Gas piping must be tested to ensure no leaks before being put into service.

Reasons for Failure:

- Failure to perform or document a pressure test.

- Test pressure too low or incorrect test duration.

- Leaks discovered during testing.

16. Gas Appliance Location [IRC 2422]:

Gas appliances must be installed in proper locations, with clearances and ventilation, to prevent fire and explosion risks.

Reasons for Failure:

- Appliance installed too close to combustible materials.

- Insufficient ventilation or improper placement in confined spaces.

- Lack of required clearances around the appliance.

17. Gas Appliance Venting [IRC 2426]:

Proper venting is required for gas appliances to remove combustion by-products safely.

Reasons for Failure:

- Incorrect venting material or size.

- Improper vent termination or location.

- Obstructed or incomplete vent runs.

Each of these points addresses critical aspects of construction and installation that are meant to ensure safety, efficiency, and code compliance. When these requirements aren't met, they can pose significant safety hazards or lead to poor system performance. Inspectors often fail installations due to lack of adherence to these specific IRC codes.